- 42.6CC - 2.3BHP

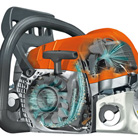

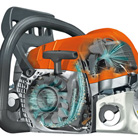

The new STIHL MS 241 C-M is the perfect companion for any professional chainsaw operator. This chain saw is compact, agile and raring to go, with M-Tronic as standard.

M-TRONIC is an electric engine management system with memory function which regulates the ignition timing and the fuel supply and automatically registers the external temperature , for optimal engine performance, great acceleration and sustained maximum torque. There is only start position on the combi-lever , so you can easily start the saw with fewer pulls on the pull cord and without switching

The STIHL MS 241 also has the new 2-MIX engine for outstanding cutting performance, plenty of torque and 20% less fuel consumption.

Other great features include: an easy to clean HD2 filter, new STIHL professional anti-vibration system, chain tensioner, 'patented' captive nuts on the chain sprocket cover, easy access quick-lock bayonet fittings on one-piece shroud, controllable oil pump, decompression valve and ergo start for easier starting.

Technical Specifications:-

Displacement : 42,6 cm³

Power output: 2,3/3,1 kW/bhp

Weight: 4,5 kg

Power-to-weight ratio: 2 kg/kW

Sound pressure level: 103 dB(A)

Sound power level: 115 dB(A)

Vibration level left/right: 2,9/2,9 m/s²

Saw chain pitch: 3/8"P

STIHL Oilomatic saw chain type: Rapid Super (RS)

-

STIHL M-Tronic (M)

For a cold start, the STIHL M-Tronic only needs one start position on the combi-lever. After starting, you can immediately power up to full speed. The amount of fuel required is precisely calculated by the system and supplied as needed. Otherwise, start in position I as usual.

-

STIHL ElastoStart

Due to compression pressure, jerky stresses occur when starting internal combustion engines. The damping element in the ElastoStart special starter grip alternately absorbs and releases force according to the compression pattern. The result is smooth, even starting.

-

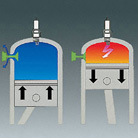

STIHL 2-MIX engine

The two-stroke engine with STIHL 2-MIX technology saves up to 20 % of fuel and reduces emissions by up to 70 % compared to STIHL 2-stroke engines of the same performance class without 2-MIX technology.

-

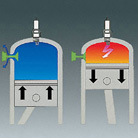

Carburettor heating (V)

By changing the chain saw from summer to winter operation, the intake air is pre-heated over the engine fins. This ensures that the carburettor does not ice up and you can continue working in freezing temperatures.

-

Controlled-delivery oil pump

Different bar lengths, wood types and sawing techniques require different amounts of oil. The controlled-delivery oil pump allows the user to select just the right amount of oil for the job at hand.

-

Side-mounted chain tensioning

Side-mounted chain tensioning makes it easy to tension the chain safely.

-

Long-life air filter system with air routing

Compared with conventional air filter systems, the service life of the filter is significantly increased.

-

Pre-separation air filtration system

STIHL long-life air filtration systems with pre-separation achieve perceptibly longer filter life compared with conventional filter systems. Air drawn in is swirled. The larger, heavier particles are ejected. The pre-cleaned air is routed to the air filter via the pre-separator duct.

-

HD2 filter

This air filter keeps even the finest dust away from the engine, ensuring a particularly long service life. Thanks to its special material, the filter can easily be cleaned by washing, for example with STIHL Varioclean and warm water.

-

Advanced combustion technology

Four overflow channels swirl the fuel-air mix before ignition, allowing for optimum combustion and highly efficient performance. The result is lower fuel consumption and high torque across a broad rpm range.

-

Compensator

This controller in the carburettor prevents the fuel-air mixture getting richer as the air filter becomes clogged. The correct quantity of fuel is delivered to the carburettor depending on the quantity of air passing through the air filter. This keeps the fuel/air ratio in the combustion mixture constant and hence also the engine power. The filter doesn't need to be cleaned until an appreciable drop in power occurs.

-

Decompression valve

The decompression valve is part of the easy starting system. The valve should be pressed before starting to reduce the compression pressure when starting, as well as reducing the effort needed to pull the starter rope. The decompression valve is semi-automatic; it must be pressed manually before starting, but then closes automatically.

-

STIHL anti-vibration system

Precisely calculated buffer zones minimise the transfer of engine and saw chain vibrations to the front and rear handles. The chainsaw therefore runs noticeably smoother. This allows the user to save their strength and work longer.

-

STIHL Ematic System

Compared to conventional bars without Ematic, the STIHL Ematic system reduces the consumption of chain lubricant by up to 50 %, depending on the type of wood and the cutting attachment used. This system comprises a STIHL Ematic or Ematic S guide bar, a STIHL Oilomatic saw chain and a variable-flow or reduced-flow oil pump. As a result, virtually every drop of chain lubricant is delivered to exactly the right spot.

-

Combi lever

As M-Tronic has electronic cold and warm start recognition, only one start position is needed on the combi lever. The exact amount of fuel is supplied on demand. You do not need to know about the status of your chainsaw and can apply full throttle straight away - even with a cold start. Because the saw is warmed up by optimum acceleration in a few seconds.

-

Stop button function

After the machine is turned off, the control lever immediately moves back into the operating position. This allows a warm machine to be restarted again immediately.

-

Captive nuts

When changing the cutting attachment, you will not risk losing the nuts on the sprocket. The MS 261 is the first STIHL chainsaw to be equipped with the captive nuts. A great advantage for all users.

-

Tool free fuel caps

Special caps to open and close the tank cap quickly, easily and without tools.